Materials With Some Concerns

Posted: March 30, 2015 Filed under: Environmental Issues | Tags: Carcinogens, Dioxin, Flexisurf, Missouri, Phthalates, Polyvinyl Chloride, PVC, Rubber, Stream Team, Tire Veneer, Tires, Toxic Chemicals, VOCs Leave a commentWe do not live in a “perfect” world but in the best circumstances each of us would be trying to push “what is” a bit more towards “the perfect” each day. When it comes to recycling materials, we often have to remind ourselves that [a] we did not cause the original material to exist and [b] keeping it out of the landfill and locked up in a useful application is the better alternative. Therefore, we continue to offer some materials that we wish were more perfect.

What I hope to do with this blog is simply share some of what we know about two material families with those who care the most about environmental issues and the complexities that should be considered. As with all of the materials that we market – it is the responsibility of the professional specifying our materials to determine the suitability of these materials for a particular application. We willingly do our part by being honest with you to the best of our own understanding about the nature of these materials.

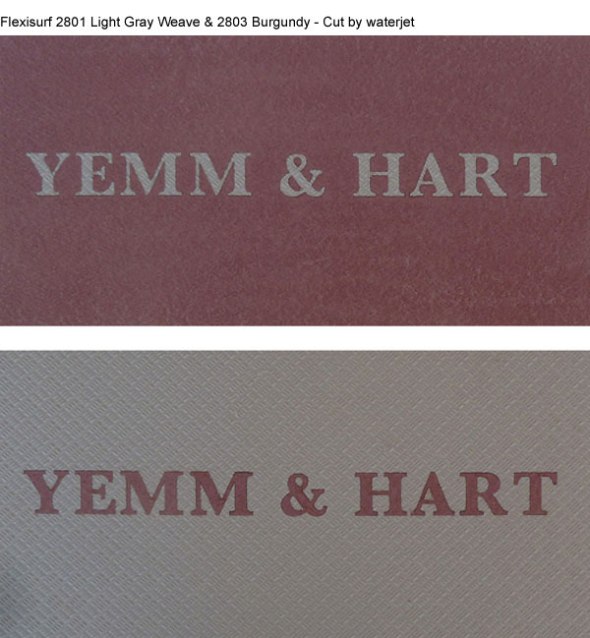

One of these materials that we are involved in getting recycled through our business, Yemm & Hart Ltd, is a PVC based material we call Flexisurf. We have this recycled material installed in our own bathroom where it has functioned for years beautifully and because it was “pre-finished” with a sealer on the production line as it was made – it is a dream to keep clean and looking nice.

As we became aware of growing concerns about PVC in general, we temporarily discontinued actively marketing Flexisurf but we would still fill orders for it with disclosure about our own concerns. As we worked through our personal feelings about being involved with PVC, we realized the point I made above. We did NOT cause it to exist and we do keep it out of the landfill where it could possibly breakdown over time and might affect the environment in some manner.

Why is PVC desirable ? PVC is strong, resistant to oil and chemicals, sunlight, weathering and is also flame resistant. PVC is all around us because it is an incredibly versatile material. Found as bottles, packaging, toys, construction materials, bedding, clothing, piping, wire coatings, imitation leather, furnishings and more places PVC third in both global plastic output and consumption. Because 57% of PVC’s mass is chlorine less petroleum is required for its manufacture than many other polymers.

What are some of the concerns about PVC generally ? Oil and chlorine are NOT what most people could call “green” substances. Their extraction, refining and by-products all pose serious concerns. One such issue of concern in its initial production is the creation of dioxin (and dioxin could also be released if the material is incinerated). Dioxin is one of the deadliest man-made poisons and it is a cumulative toxin. It stays in the body for a long time and can concentrate in food chains at the highest levels.

Another issue that has been identified with PVC is the use phthalates added to make it flexible. It’s often reported that no other plastic presents such a direct environmental and human health threat as PVC does.

So it really is the manufacture of PVC to begin with that is the issue of most concern. Recycled into the sheet form that we sell it as is NOT the real concern. Why ? It’s highly stable and not likely to biodegrade. Items made from PVC will retain their form for decades and the breakdown that does occur is into smaller and smaller pieces.

Recycling PVC is difficult and dangerous and requires special equipment to make its reprocessing safe for the employees of the facility and to prevent any emissions from entering the atmosphere. That is why only 1% of all the PVC created is ever recycled. It is likely your local recycling center will NOT even accept #3 (PVC) plastics from you.

Rubber is another material that we are involved in recycling through our business. We call our recycled rubber material Tire Veneer (for obvious reasons). Recently a few reasons for concern regarding rubber have come to my attention. I already knew from local history that making piles of tires usually culminates in tires burning and sending lots of smoke up into the air. Our Missouri Dept of Natural Resources won’t allow that practice any longer. When we are working at cleaning trash out of waterways for our state Stream Team organization, we are given financial assistance to defray the cost of properly disposing of the numerous tires that many people seem to think nothing of dumping into ditches, on back roads or into our streams and rivers.

Recently, some concerns have been expressed about the use of crumb rubber (tires recycled by grinding them up into crumbs) in applications where children will be playing. On the positive side the resilience and cushioning ability of the material had been the reason it was specified to benefit from its ability to help prevent injuries. The crumb rubber form of the recycled rubber material has been used for athletic fields, as garden mulch and in children’s playgrounds.

As with PVC, there is more concern related to manufacturing issues than with subsequent use of the reclaimed material. Tire crumbs do contain volatile organic hydrocarbons (VOCs) with carcinogenic potential. Evidence of VOCs in crumb rubber has been extracted under laboratory conditions. Health reports from workers in the rubber fabrication industry and also within the rubber reclamation industry describe the presence of VOCs and some toxic elements that can become airborne. Studies at some tire reclamation sites have reported leaching of similar chemicals into the ground water. Occupational studies document potential health effects ranging from skin, eye, and respiratory irritation to implication in the origination of three forms of cancer.

Studies have been conducted that resulted in some recommendations that the use of reclaimed crumb rubber from tires should be limited when related to human exposure in outdoor applications. The summertime heating of the material could amplify the release of VOCs from crumb rubber installations. And there are advisories against using crumb rubber for mulch when growing nursery food plants.

What about applications for recycled rubber in sheet form flooring ? I sincerely appreciated the response of Cynthia Phakos of Koffka Phakos Design in Los Angeles CA on the US Green Building Council’s website (link in the Information Resources section at the end of this blog). She said –

[1] Recycled rubber flooring is very green as it diverts used products from the landfill, and is a durable, renewable material.

[2] There can be off-gassing of VOCs which could be harmful if one has sensitivities. These odors will dissipate over time into the atmosphere.

Her support for that application did note that various manufacturers’ products can vary in their environmental and health impacts and that some testing of rubber flooring material in a basement installation has proven it to be an acceptable use. She is correct in noting that “colored granules” are there for aesthetic purposes and the that highest recycled content would be in the solid Black variety. It is also noted that recycled rubber flooring has a longer life (approx 20 yrs) than vinyl or carpet products.

We find recycled rubber sheeting useful as a weed barrier and to soften concrete steps. We have also upholstered a hard plastic chair and drum table, both with good results.

Life is full of complexities and trade-offs. We feel that both Flexisurf and Tire Veneer are excellent materials for their durability and ease of maintenance. And of course, we are totally committed to bringing you recycled content with ALL of our materials.

~ Information Resources

“PVC plastic’s environmental impact” posted at Green Living Tips on Jan 4, 2010 – http://www.greenlivingtips.com/articles/pvc-and-the-environment.html

“Artificial Turf: Exposures to Ground Up Rubber Tires – Athletic Fields, Playgrounds, Garden Mulch” posted at Environment and Human Health Inc – http://www.ehhi.org/reports/turf/

“Is recycled rubber flooring a green and healthy choice? We’re considering it for a basement living space.” at US Green Building Council’s “Green Home Guide” – http://greenhomeguide.com/askapro/question/is-recycled-rubber-flooring-a-green-and-healthy-choice-we-re-considering-it-for-a-basement-living-space

***

Blog author ~ Deborah Hart Yemm is co-founder of

Yemm & Hart, a green materials producer

***

Spring Planting in the Forest

Posted: March 22, 2015 Filed under: Trees | Tags: Erosion, Forest Management Plan, Government Assistance, Planting, Riparian, Soil, Trees Leave a commentI thought I’d share my family’s story as a way of explaining why I never got around to posting a blog here last week. My family has spent most of the last week planting trees. Back in 2002, we entered into a federal government program to reduce soil erosion and contracted to have 18,000 mixed hardwood trees planted in the riparian buffers of our major perennial stream. For two years after that, my husband mowed between the rows of trees because we refused to use herbicides to kill off the Fescue and that was the compromise we had arrived at with the government to allow us not to do that and still receive their financial assistance. My husband also walked the rows each year and hand-planted seedlings to replace any of the trees that had died with new trees. During that phase we added in evergreens and the flowering trees, Dogwood and Redbud.

It was during that time that I was pregnant with our youngest and we were searching for a name for him. For personal reasons related to his siblings, my husband wanted a name that began with “T”. We have a lot of awesome rock here on our farm and one day he came home to me after some hand-planting work and said – “I have it !! We can name him Tree Stone !!” I said no, no, no that is not a proper name and then inspired said, “Let us call him Treston”. And that story in why in some of our most fun and humorous moments we will sometimes refer to him as “Tree Stone” or “Plant Rock”.

Last year the crazy restrictions and conditions for receiving state government assistance to plant more trees caused us to abandon that plan after many hours of researching and planning by my husband because it simply did not make economic sense (it was going to cost us a lot of money that we did not have at the time) and the risks it entailed (having to repay monies received and even pay penalties on it) if we did not perform precisely as instructed were simply not acceptable. Encouraging us even more, was the fact that the contractor who was supposed to do that work for us, simply would not return our calls. It was too large of a project to go forward with all things considered. So my husband and two sons hand-planted 500 evergreen trees. This caused my husband to grow concerned that he would not live long enough to fulfill his vision of replacing our pastures with new forest with what remains of his own lifetime at such a pace.

My husband has been in the midst of this year’s project for months with lots and lots of planning in advance. We even spent an afternoon with an older man and his wife in a neighboring county. Interestingly, we first met this man back in 2002 but decided not to work with him because his values at the time did not seem aligned with ours. Now this year, my husband sought to learn everything he could from this man’s experience in machine planting trees. Not only did we visit him but several times my husband had long telephone conversations with him before we were ready to move forward with financial investments into this year’s planting.

We bought an implement for tree planting. My husband modified it to make it safer and more useful for including our youngest son in the family project even including a seat belt for him. Beginning in late February, after we had already ordered and paid for this year’s bare root seedlings, we had almost 3 weeks of snow continually on the ground – first 7″, followed by 5″. We had lots of single digit and teen temperatures during that time and there was a very, very slow melting of that snow, immediately followed by a significant rainfall.

When asked about when I thought we should pick up our trees and begin planting, I had suggested to my husband that he not pick up the trees until this week. However even though I thought we needed more drying out time but he went ahead picked the trees up at the nursery last week. Now the clock was ticking against us for the trees need to be put into the ground as quickly as possible once they are out of cold storage at the nursery. My husband still made good use of the extra “early” days by doing some replacement hand-planting of the rows that he and our sons hand-planted during last year’s effort and also hand-planting 25 Cypress trees into a wetland area.

By Sunday, we tried to start planting Walnuts according to his plan which was to start in the bottoms near some of the trees we had planted back in 2002. The field was simply too wet. I immediately got our Suburban stuck. At least we managed to do all the training sessions that first day – mine for shuttling trees and water, my oldest son for driving the tractor and my youngest son (age 10-1/2) for managing the seedlings, handing the appropriate trees to my husband and telling him the moment to “plant” in order to keep a specific distance between trees and our son’s instructions included picking a “wildlife” specie to be interspersed after every 6 hardwood trees.

You can get an idea of scale by noticing the little house in the red square at the bottom left of this image. This is only about half the entire length of this particular field. We will plant the other half in some subsequent year.

Eventually the impossible wetness of the field caused my husband to give up on the idea of getting any more planting done other than a very tiny start we had made on Sunday afternoon. He’s a pretty persistent, determined kind of guy so giving up entirely wasn’t easy for him to do but the reality could not be denied. The drag of the plow on the planter in that mud would cause the tractor’s tires to spin even though thankfully the tractor never became stuck so that we ended up with a bigger problem on our hands. We didn’t even try to go out to plant on Monday but gave the fields a warm dry day to become more workable. Then, our oldest son (age 14) suggested that we really ought to start at the uphill part of the field or at least in the middle. My husband was able to agree to a Plan B to plant in the middle of the field but in an attempt to keep the spacing on his original plan, he went out and flagged the spacing for two of those rows according to the downhill Walnut row.

On Tuesday afternoon, we went out and started uphill from the middle with the Northern Red Oaks and managed to get through the Black Gum after about 4 hours as the cold wind and approaching darkness put an end to that day’s work. On Wednesday, we expected rain by 2pm for the next 48 hours and so we got an early start, expecting to have to quit early. The field was the driest yet and so we turned back downhill from the middle. Good fortune kept the rain at bay and we ended up being out there for 9 hours until dark. There were some light sprinkles that came but nothing strong enough to put a stop to the day’s work. However it did rain that night and was lightly raining on Thursday.

So on Thursday, my sons and I were given the “day off”. My husband went out and hand-planted the “wetter” areas that gave us so much trouble on Sunday (the Walnut rows) by hand. He admitted that it would take many weeks for that area to actually dry out. On Friday, we got an early start – not as early as Wednesday but still put in 7 hours (working until dark). We finished the big field but still had a lot of seedlings left over, so we went to Plan B below for the excess trees.

By the end of Friday, there were only 300 trees left and so my husband and older son took care of them in about 2-1/2 hours on Saturday and allowed myself and the youngest son to stay home. These trees went into the field to the northeast of my deceased in-laws old log cabin.

Here’s the tally for this year.

Total Hardwood Trees = 2,350. About 200-300 per species. The mix included – Black Walnut, Black Cherry, White Oak, Mixed Hickory, Shumard Oak, Sweet Gum, Northern Red Oak, Black Gum, Black Oak and Chinkapin Oak.

Total “Wildlife” Species = 360. The mix included – Black Chokeberry, Black Locust, Eastern Wahoo, False Indigo, Flowering Dogwood, Red Mulberry, Redbud, Slender Bushclover, Smooth Sumac, White Fringetree and Wild Plum.

And another 25 Cypress trees in the wetlands area.

The work is not yet entirely complete. As I write this, my husband is back out in the field on the tractor because we can’t leave the plowed groove “open”. The little rodent like critters would utilize that as a “highway” to munch on the roots ending the future of our trees. The diagram above represents the slow and tedious process as he uses one of the front tires on the tractor to close the plowed grooves. The dots represent seedlings in a row.

The long-range overall plan is to replant all the Fescue pasture that my husband and in-laws created back in the late 1970s/early 1980s in trees so that we won’t have to burn the fields to keep them open anymore. We will do that planting over about 5-6 years time in sections of about the same size or quantity as we did this year. By doing this intentional planting, we are modifying what Nature would do in returning fields to forest. In the natural cycle, Cedars, Locust, Sumac and Persimmons are among the first to take root in a fallow field. We have stands of tall Pines here that are described as succession trees, these are what grow next in the areas that once were crop fields. Later on the hardwoods begin to take hold. This cycle would create some marketable timber after 100-150 years of time elapsed.

At this time, hardwoods have the most commercial value as timber. We have planted a lot of hardwoods including quite a few species of Oak which do well and are native here. We are protecting the farm in perpetuity as long as there are descendants to live here as stewards of this extraordinarily beautiful land. Our sons will certainly be able to follow our Forest Management Plan which will have them in another logging cycle in about 30 years and therefore, they may achieve the long-term funding benefits for the continuation of this farm twice in their lifetimes. The trees my sons have been involved in planting may benefit them at the end of their lifetimes or will be of financial usefulness to their children some day.

Most people do not have such a long-view regarding what they do on the land they have possession of. I believe that is why it is somewhat rare for anyone to put so much time, effort and money into planting trees – they see no personal benefit in doing so. Certainly, serious environmentalists will always consider planting trees beneficial for the planet and all her creature’s health and vitality.

***

Blog author ~ Deborah Hart Yemm is co-founder of

Yemm & Hart, a green materials producer

***

Tar Sands & Train Wrecks

Posted: March 8, 2015 Filed under: Environmental Issues | Tags: Canada, Conscious Capitalism, Crude Oil, DOT-111, Fracking, Free Trade Agreement, Fresh Air, Government, Jim Prentice, Jonathan Waldman, Keystone Pipeline, Lac-Megantic, Marcus Stern, Money, Morning Edition, North Dakota, NPR, NY Times, Politics, Refineries, Regulation, Safety, Tanker Cars, Tar Sands, The Container Store, Trains, Wrecks Leave a commentOne of my family’s favorite movies is Unstoppable with Dezel Washington. That movie tracks somewhat closely a real life incident that it is based on the CSX 8888, also known as the Crazy 8s incident. In both the movie and the incident there are tanker cars carrying molten phenol and an un-manned “runaway” train. The reasons this happened are the same in both versions – a misaligned switch, an engineer leaving the cab to address it and thinking that applying the independent air brake would be adequate.

The movie is a gripping, seat of your pants drama about how ill prepared the powers that be are to rapidly respond to the inevitable shouldn’ts that still happen. It turns out that when it comes to railroad issues, the powers that be are the railroads themselves (the fox guarding the chicken coop – the serious danger policed by the source of that danger).

I wanted to watch the Unstoppable movie again after I recently listened to the Feb 25, 2015 episode of NPR Fresh Air titled “A Hard Look At The Risks Of Transporting Oil On Rail Tanker Cars” which was an interview of the investigative journalist, Marcus Stern. And to complicate things even more, the railroads don’t have 100% control over the “source” of the danger highlighted in this segment but control over the quality of those tanker cars is in the hands of those whose product is inside those tanker cars.

Train wrecks involving tanker cars are increasing in frequency. The most note-worthy of recent disasters in the interview occurred in Lac-Megantic Quebec Canada and involved a train that was unattended, which experienced a failure of its brakes that sent it traveling downhill at speeds reaching 60 mi/hour whereupon it encountered a curve causing it to derail, killing at least 47 people in a bar there on a Saturday night in July 2013.

It is not surprising to discover that BIG money obscures the dangerous risks now taking place. The onset of fracking in North Dakota and the existence of East Coast refineries that were not competitive processing imported oil and the convenience of rail lines and available tank cars to connect the two . . . how BIG is the payoff ? – this whole economic system is “worth tens of billions of dollars, perhaps hundreds of billions of dollars” according to Stern.

So how many tanker cars are we actually talking about ? In 2008, there were 9,500 rail cars carrying crude oil. In 2014, just 6 years later, that number had jumped to 400,000. And regarding each train, they are now often 100 tanker cars extending a mile in length carrying a combined total of as much as 3 million gallons. Does this represent some change from trains only a few years ago ? Yeah, it does. In the past when hauling crude oil by rail, there might be only a couple of tankers and they’d be split up over the length of the train, reducing the risk.

Is there some characteristic that makes the North Dakota crude more dangerous. Well, yeah. It is known as “light oil” and it is a lot like gasoline. It’s actually a mixture of oil and liquid natural gases (methane, butane, propane) which are suspended in the oil. As this travels the thousands of miles from North Dakota to the East Coast, the gas part begins to separate from the liquid part leaving a gaseous blanket of propane sitting on top of the liquid oil. A breach and a spark and you have fireballs shooting hundreds of feet in the air with flaming oil shooting in all directions and such explosions can continue for several days. The emergency responders can’t do anything more than keep people away and let it burn out.

Is there something about the tanker cars being used that would make a breach more likely ? Yeah, there is. The most common model is the DOT-111 which was designed back in the 1960s for non-flammable liquids like corn syrup. This particular design is highly likely to rupture in a derailment because the shell is not thick enough. The opening at the top through which the oil is loaded into the tanker can break off in derailments. The valves don’t shut properly. At the bottom, there’s a fitting that is used to remove the oil at the refinery that also tends to break. Both ends of the tanker car need to reinforced as well. The DOT-111 is used by producers and refiners because of the economics – there are simply a lot of old DOT-111s available. Presently as many as 100,000 of them are transporting oil.

Why isn’t anyone doing something about the use of these dangerously inappropriate tanker cars ? The railroad did put into effect in Oct 2011 a mandate for tougher cars with thicker shells, though not nearly as thick as they need to be nor are there the other improvements that could increase the safety of transporting fuel on rails. And the mandate is very limited in scope – it only applies if a “new” car is built. Then, that new tanker must meet the new standards. The problem is that there are still hundreds of thousands of the old “legacy” cars still out there and they are active on the rails.

Here’s where it gets interesting . . . although the railroads are concerned, getting the tanker cars phased out and replaced is NOT under their control. The “shippers” (the refineries that take them and the producers that load them in North Dakota) are the owners of these railcars. Therefore the burden of upgrading these falls on them. And once again, “it’s the money” preventing increases in safety because it is the owners are the ones that are resisting the upgrades. How much would it cost them ? Maybe $3 billion dollars to upgrade all of the tankers.

To make this division of responsibility a bit clearer – the railroads own the track, have the right-of-ways and the locomotives. And railroads cannot legally refuse to carry any specific cargo but must allow their tracks to be open to the transportation of goods generally. Another issue of concern is that the viability of bridges that railroads also own is their responsibility. The railroad is the only party that can tell you whether the bridge is safe and there are no engineering standards for railroad bridges. The federal government does not inspect the bridges nor does it enforce any regulations related to their safety.

Yeah, what about our government ? Isn’t there something they could do ? The regulatory process includes “negotiated rulemaking”. What this means is that there are a lot of secret behind-closed-door meetings between industry and policy makers. That gives the industry a very loud voice which allows them to delay, dilute, or delete provisions that they object to. And there is gridlock in the process. Here’s an example, the Department of Transportation (regarding anything related to crude-by-rail) has not been able to get these regulations officially functional for more than a year and a half. It is no surprise that the rail-related industries put millions of dollars into lobbying in Washington to keep everything going in the direction of their best interests.

After Lac-Megantic, the Department of Transportation did issue an emergency order that trains may not be left with their engines running while sitting unattended on tracks without “specific” permission. Yet this practice continues and if the railroad receives a complaint about it, they will assert that they were “allowed” to do that. Why ? Because it says in the small print only that they have to have “a plan” (inconveniently in a drawer somewhere ?) for leaving the railroad cars unattended with their engines running.

Also mandated after Lac-Megantic, the railroads must notify state emergency officials whenever they’re going to be sending any train through a state that has more than a million gallons of oil being transported. But anything less than that and the states won’t get notified. Even when notifications are transmitted that’s no guarantee that the information will reach the local community level.

Recently President Obama vetoed the bill approving the Keystone XL tar sands oil pipeline modification. A Senate vote to override the veto fell short on Wed, March 4th. That certainly is okay with me. I wonder however who that pipeline actually benefits financially. What I found was that it is an indication of the power of the oil industry over this country. The very first order of business when the Republicans took over the Senate was a bill related to an oil pipeline for a foreign oil company to get their product passed through our country to the Gulf coast refineries and ports for export to other countries. Personally, I wonder if the whole Keystone issue isn’t simply a distraction from the more serious concerns that Stern highlighted in his rail tanker car report.

Officially, the reason the president vetoed the bill “is that it circumvents a long-standing administrative process for evaluating whether or not infrastructure projects like this are in the best interest of the country.”, according to White House Press Secretary Josh Earnest. In an op-ed piece in the NY Times, Jonathan Waldman suggests that “Getting behind a law holding pipelines to higher standards seems an executive act far more courageous than a veto.” while acknowledging that “In the generation since, regulations have actually gotten laxer . . .”

In the Marcus Stern interview, one of the arguments for a pipeline – not needing to transport by rail any longer was ably refuted. He said – “… the reasons I think that producers and refiners have turned to rail is because pipelines are just so difficult to get approved. You can look at the Keystone XL Pipeline – the big debate over it – and it’s become a lightning rod for this whole discussion. But building pipelines is very contentious. And in addition to that, it takes a lot of time to do it. There’s a big upfront expense. And by the time they were putting pipelines into North Dakota, the North Dakota play might be played out.”

A lot of the Keystone Pipeline already exists as part of an infrastructure that has been built over the last 50 years. All the uproar is about “straightening” it and adding the final completing link to the Gulf Coast. So this pipeline infrastructure project just may not really make either economic or environmental sense. The Alberta Canada Premier, Jim Prentice, puts the issue bluntly this way – “under the Free Trade Agreement . . . this is a free-market product that’s moving across the North American continent one way or the other. Right now, in the absence of pipeline capacity, it will be increasingly carried by railcars. That is not the safest way. It’s not the most environmentally responsible way to carry hydrocarbons”. And it is no surprise that he believes that “… pipelines are an infinitely better choice”. Clearly, blocking further progress to finish the Keystone pipeline won’t ever prevent Canada from extracting its tar sands oil.

Jonathan Waldman asserts – “Pipelines are the safest way to move oil. They’re an order of magnitude more reliable than trains, and trains are an order of magnitude more reliable than trucks.” Still, whether it is rail or pipeline the ways of regulation in this country are discouraging – “dramatic explosion, calls for reform and powerful resistance”. Waldman makes some reassuring points about the state of technology to make pipelines safer – “smart pigs” that “can record tons of information, and capture unprecedented levels of detail” and are “more agile” – able to traverse narrow pipelines and make tight turns. He notes that leak detection software has gotten better and is now running on big databases that can monitor developing corrosion in pipelines over time.

I think back to Marcus Stern’s point about pipelines in general and it would seem to me that tanker railcars are the more “flexible” choice to move product around, whether to the East Coast or the Gulf Coast. Why not strengthen the overall safety of the rail system ? – the tanker cars, the bridges, the travel ways through the population centers around refineries – why not upgrade the whole rail system ? if the US is going to be “in the petroleum producing business” for a long time any way but perhaps continuously moving around to develop different geographical areas of our energy reserves. I’m not a fan of fracking – not at all !! – but my feelings about it aren’t going to stop it as long as it is reducing our energy dependence on politically volatile areas like the Middle East and of course if there’s a lot of money to be made and lobbying of politicians to support that effort.

Plastic is a petroleum product. Therefore, it would seem safe to assume that when we recycle plastic, we are extending the life of that already extracted natural resource. When we use it for serious construction purposes – such as restroom stall partitions – it should mean that there is less of a need to extract “new” petroleum. Or so one might hope – though markets operate on more and more stuff being generated as a rule. The Container Store believes in Conscious Capitalism and one of the ways they show that by their actions is by using Yemm & Hart’s 513 Tornado for vanity countertops in their retail establishment’s customer restrooms. Funny, somehow the color reminds me of oil flowing . . .

~ Information Resources

Unstoppable (2010 film) – http://en.wikipedia.org/wiki/Unstoppable_(2010_film)

The CSX 8888 Incident – http://en.wikipedia.org/wiki/CSX_8888_incident

A Hard Look At The Risks Of Transporting Oil On Rail Tanker Cars – interview w/Marcus Stern at NPR Fresh Air – February 25, 2015 – http://www.npr.org/2015/02/25/389008046/a-hard-look-at-the-risks-of-transporting-oil-on-rail-tanker-cars

Obama Vetoes Keystone XL Bill, But Fight over Climate-Threatening Oil Pipeline Isn’t Over – posted at Democracy Now.org on Feb 25, 2015 – http://www.democracynow.org/2015/2/25/obama_vetoes_keystone_xl_bill_but

Keystone XL Pipeline Benefits U.S. And Canada, Alberta Premier Says – interview with Jim Prentice, Alberta Premier for NPR Morning Edition on Feb 04, 2015 – http://www.npr.org/2015/02/04/383724544/keystone-xl-pipeline-benefits-u-s-and-canada-alberta-premier-says

Don’t Kill Keystone XL. Regulate It. by Jonathan Waldman posted March 6, 2015 – http://www.nytimes.com/2015/03/06/opinion/dont-kill-keystone-xl-regulate-it.html

What We Stand For – blog by The Container Store – http://standfor.containerstore.com/category/conscious-capitalism/

***

Blog author ~ Deborah Hart Yemm is co-founder of

Yemm & Hart, a green materials producer

***

Recent Comments